When buying tape online, there are a wide range of options we stock at Proton Packaging. When purchasing in bulk, making a hasty decision can be costly or even affect business operations. That’s why we created this comprehensive packing tape guide – to help ensure you choose the right tape for your specific task, environment, and industry.

Part 1: Quick Reference Guide

| Tape Type | Use Case | Industries / Applications |

| Polyprop Tape | General packaging and sealing | Retail, E-commerce, Warehousing |

| Low Noise Tape | Quiet sealing, less disruptive | Retail, Offices, Warehousing |

| Vinyl Adhesive Tape | Heavy-duty sealing and waterproofing | Logistics, Manufacturing, Outdoor Use |

| Custom Shipping Tape | Branded and secure packaging | E-commerce, Branding, Retail |

| Cloth Duct Tape | General repairs, heavy-duty bonding | Construction, Automotive, DIY |

| Electrical Insulating Tape | Insulation for electrical components | Electrical, Manufacturing |

| Paper Adhesive Tape (Self Seal) | Eco-friendly sealing | Environmentally conscious businesses |

| Gummed Kraft Paper Tape | Eco-friendly, tamper-evident sealing | E-commerce, Moving |

| Tissue Tape | Lightweight, non-damaging | Retail, Art & Craft, Office |

| Masking Tape | Temporary bonding and protection | Painting, Automotive, Electronics |

| Aluminium Adhesive Tape | Heat-resistant applications | Industrial, HVAC |

| Adhesive Copper Tape | Electrical conductivity | Electronics |

| Foam Tape | Cushioning and sealing | Furniture, Electronics |

| Crossweave Reinforced Tape | Heavy-duty strength | Construction, Industrial |

| Double Sided Tape | Invisible bonding | Offices, Retail |

| Hot Melt Adhesive Tape | Fast bonding | Packaging, Manufacturing |

| Acrylic Adhesive Tape | UV and weather resistance | Outdoor Use |

| Solvent Adhesive Tape | Strong bonding in tough conditions | Industrial, Automotive |

Part 2: Tape Options

1. Polyprop Tape

- Adhesive Type: Acrylic (water-based)

- Key Features: Transparent, strong adhesion, resistant to tearing

- Typical Sizes:

- Buff: 50mm x 66m, 50mm x 132m, 50mm x 990m

- Clear: 50mm x 66m, 50mm x 132m, 50mm x 990m

- Red (“Fragile”): 72mm x 990m

- White (“Fragile”): 72mm x 990m

- Use Cases: General-purpose sealing for cartons and packages; suitable for both manual and machine application

- Industries: Retail, e-commerce, logistics

2. Low Noise Tape

- Adhesive Type: Acrylic

- Key Features: Quiet unrolling and great for shared spaces

- Typical Sizes:

- Buff: 50mm x 66m, 50mm x 132m

- Clear: 50mm x 66m, 50mm x 150m

- Use Cases: Ideal for use in offices and retail environments where noise reduction is important

- Industries: Retail, offices, warehousing

3. Vinyl Adhesive Tape

- Adhesive Type: Solvent-based

- Key Features: High durability, resistant to UV and water, ideal for outdoor use

- Typical Sizes:

- Buff: 50mm x 66m, 75mm x 66m

- Clear: 50mm x 66m, 75mm x 66m

- Use Cases: Suitable for sealing items that require protection against the elements

- Industries: Logistics, outdoor shipping, construction

4. Custom Shipping Tape

- Adhesive Type: Acrylic or Solvent-based

- Key Features: Custom printed for branding and security

- Typical Sizes:

- Custom sizes available upon request

- Use Cases: Used for businesses that need a branded look for their shipments

- Industries: E-commerce, retail, branding

5. Cloth Duct Tape

- Adhesive Type: Solvent-based

- Key Features: Highly adhesive, durable, tear-resistant

- Typical Sizes:

- 50mm x 25m, 75mm x 25m

- Use Cases: General-purpose repair tape, often used for sealing boxes or repairs

- Industries: Construction, automotive, DIY

6. Electrical Insulating Tape

- Adhesive Type: PVC-based

- Key Features: Insulation for electrical components

- Typical Sizes:

- 19mm x 20m

- Use Cases: Electrical insulation for wires and cables

- Industries: Electrical, manufacturing

7. Paper Adhesive Tape (Self Seal)

- Adhesive Type: Solvent or Acrylic-based

- Key Features: Eco-friendly, water-resistant, recyclable

- Typical Sizes:

- Buff: 50mm x 25m, 50mm x 50m

- Use Cases: Suitable for sealing boxes in an environmentally conscious manner

- Industries: E-commerce, moving, eco-conscious industries

8. Gummed Kraft Paper Tape

- Adhesive Type: Water-activated

- Key Features: Eco-friendly, strong bond, tamper-evident

- Typical Sizes:

- 50mm x 100m

- Use Cases: Ideal for sealing boxes with an eco-friendly approach

- Industries: E-commerce, moving, eco-conscious industries

9. Tissue Tape

- Adhesive Type: Acrylic

- Key Features: Lightweight, non-damaging to surfaces

- Typical Sizes:

- 12mm x 50m

- Use Cases: Suitable for lightweight sealing and applications where surface protection is important

- Industries: Retail, art & craft, office

10. Masking Tape

- Adhesive Type: Rubber-based

- Key Features: Easy removal, suitable for delicate surfaces

- Typical Sizes:

- 24mm x 50m, 48mm x 50m

- Use Cases: Ideal for painting and surface protection tasks

- Industries: Automotive, painting, electronics

11. Aluminium Adhesive Tape

- Adhesive Type: Solvent-based

- Key Features: High-temperature and heat-resistant applications

- Typical Sizes:

- 48mm x 50m

- Use Cases: Suitable for sealing ducts and insulation in HVAC systems

- Industries: Industrial, manufacturing, HVAC

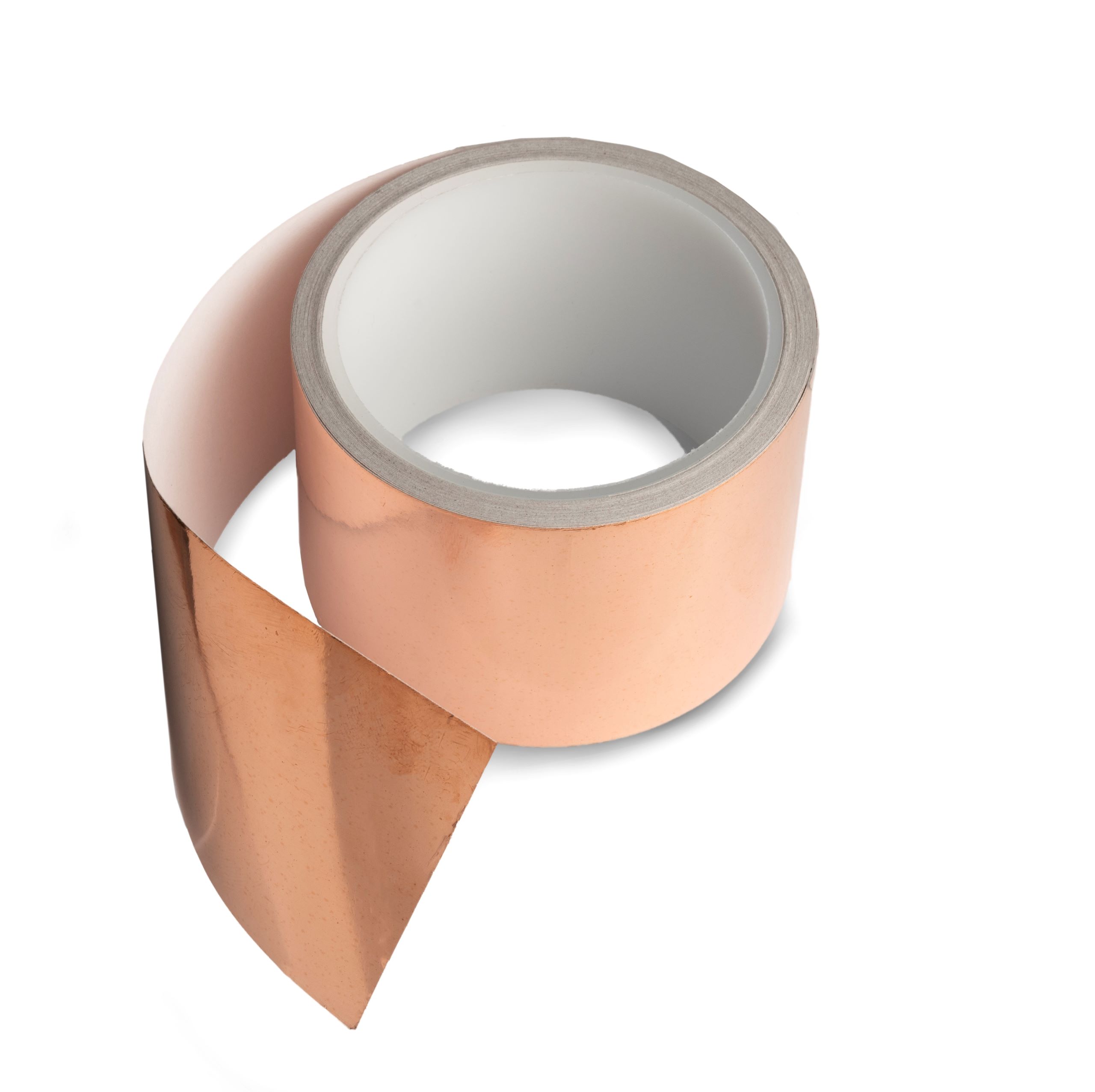

12. Adhesive Copper Tape

- Adhesive Type: Conductive adhesive

- Key Features: Electrical conductivity, shielding from interference

- Typical Sizes:

- 19mm x 10m

- Use Cases: Used in electronics for shielding and grounding

- Industries: Electronics, electrical engineering

13. Foam Tape

- Adhesive Type: Acrylic

- Key Features: Cushioning and sealing in one

- Typical Sizes:

- 12mm x 5m

- Use Cases: Suitable for sealing and cushioning applications

- Industries: Furniture, electronics, automotive

14. Crossweave Reinforced Tape

- Adhesive Type: Solvent-based

- Key Features: Heavy-duty strength and tear-resistance

- Typical Sizes:

- 50mm x 66m

- Use Cases: Ideal for heavy-duty sealing and bundling

- Industries: Construction, industrial

15. Double Sided Tape

- Adhesive Type: Acrylic

- Key Features: Bonding surfaces without visible tape

- Typical Sizes:

- 12mm x 50m

- Use Cases: Suitable for mounting and bonding applications

- Industries: Offices, retail, construction

16. Hot Melt Adhesive Tape

- Adhesive Type: Hot melt (synthetic rubber)

- Key Features: Quick bonding and sealing, high tack

- Typical Sizes:

- Buff: 25mm x 66m, 50mm x 66m, 50mm x 200m

- Clear: 50mm x 66m, 50mm x 990m

- Use Cases: Suitable for sealing cartons and packages

- Industries: Packaging, logistics, manufacturing

17. Acrylic Adhesive Tape

- Adhesive Type: Acrylic (water-based)

- Key Features: UV and weather-resistant adhesive

- Typical Sizes:

- Clear: 12mm x 33m, 12mm x 66m, 25mm x 66m, 50mm x 66m

- Red (“Fragile”): 72mm x 990m

- White (“Fragile”): 72mm x 990m

- Use Cases: Suitable for sealing boxes in outdoor conditions

- Industries: Outdoor use, construction, automotive

18. Solvent Adhesive Tape

- Adhesive Type: Solvent-based (natural rubber)

- Key Features: High bonding strength, temperature-resistant, clean removal

- Typical Sizes:

- Buff: 50mm x 66m, 50mm x 200m

- Clear: 50mm x 66m, 50mm x 990m

- Use Cases: Suitable for sealing cartons and packages in various conditions

- Industries: Packaging, logistics, manufacturing

Part 3: Tips & Best Practice

In addition to choosing the right tape, there are important considerations around storage, application, and environmental conditions. Ignoring these can lead to poor adhesion, wasted materials, and unnecessary costs.

Storage Considerations

- Store low noise and vinyl tapes in a cool, dry place to preserve adhesive performance

- Gummed kraft paper tape must be kept in a moisture-controlled environment, as its adhesive is water-activated

When Not to Use Specific Tapes

- Do not use paper adhesive tape for heavy-duty packaging

- Avoid electrical insulating tape for sealing cartons – it is not designed for packaging applications

Tips for Choosing the Right Tape

- For heavy-duty shipping, use crossweave reinforced tape or vinyl adhesive tape

- For environmentally conscious packaging, choose self-seal paper tape or gummed kraft paper tape

- For branding and security, custom printed tape enhances visibility and tamper resistance

Industry-Specific Recommendations

- Retail environments benefit from low noise and tissue tapes

- Electronics manufacturers commonly use aluminium or copper adhesive tapes for protection and conductivity

Part 4: How Packing Tape Works

Pressure-Sensitive Adhesives Explained

Most common packing tapes – including polyprop (PP), low noise, and vinyl – are classed as pressure-sensitive adhesives.

This means the tape will not bond correctly unless pressure is applied during application.

When sealing a carton:

- The tape must be smoothed firmly onto the surface

- Pressure should be applied using your hand or the flap on a tape gun

Tape guns include pressure flaps for a reason – they activate the adhesive by forcing it into the cardboard fibres.

Many reports of “tape not sticking” are caused by incorrect application rather than faulty tape.

Temperature and Adhesive Performance

Temperature has a major impact on how well tape performs. Using the wrong adhesive for the conditions is one of the most common causes of seal failure.

Ideal Operating Temperatures by Adhesive Type

Economy / Acrylic Adhesive

- +15°C to +65°C

- Water-based and environmentally friendly

- Includes standard polyprop tape and premium acrylic low-noise tapes

- Not suitable for winter or cold storage

General Purpose / Hot Melt Adhesive

- +15°C to +50°C

- Solvent-free synthetic rubber adhesive

- High initial tack

- Not recommended for cold environments

Low Noise Tape

- +15°C to +65°C

- Quiet off the roll

- Combines the strength of polyprop with the quiet unwind of vinyl

- Temperature-sensitive

Solvent Adhesive (Vinyl Tape)

- -20°C to +50°C

- Slow-release, long-term adhesive

- Performs reliably in cold conditions

- Stores better and lasts longer than acrylic or hot melt

- Best pressure-sensitive option for winter use

Premium PVC Tape

- -25°C to +50°C

- Hand-tearable

- Extremely durable for demanding environments

The Best Tape for Cold Conditions

Cold air increases moisture in cartons, which weakens standard pressure-sensitive adhesives. For cold warehouses, unheated units, or winter shipping, the most reliable options are:

Why Gummed Kraft Paper Tape Is So Effective

Gummed paper tape works differently to standard packing tape:

- The adhesive is activated by moisture

- Once applied, it bonds directly into the cardboard fibres

- The bond becomes so strong that removing the tape often tears the carton itself

Instead of being affected by damp cartons, gummed tape uses moisture to strengthen the seal.

This is why major fulfilment operations rely on gummed paper tape for cold and high-volume shipping – it delivers consistent, tamper-evident results.

Practical Takeaways

- Always apply firm pressure when sealing cartons

- Avoid acrylic and hot melt adhesives in winter

- Recommend solvent vinyl tape for cold conditions

- For maximum strength, security, and reliability, gummed kraft paper tape remains unmatched

Frequently Asked Questions About Packing Tape

What is the best packing tape for boxes?

The best packing tape depends on the weight of the box, storage conditions, and temperature. For general use, polyprop or low noise tape works well. For heavy or cold conditions, solvent adhesive or gummed kraft paper tape is more reliable.

Why does packing tape sometimes not stick properly?

Packing tape may fail if insufficient pressure is applied during sealing or if the tape is used outside its recommended temperature range. Cold conditions and damp cartons can significantly reduce adhesion for some tape types.

What is pressure-sensitive packing tape?

Pressure-sensitive packing tape relies on applied pressure to activate the adhesive bond. Without firm pressure during application, the tape may not adhere correctly to cardboard surfaces.

Which packing tape works best in cold weather?

Solvent adhesive vinyl tape performs best in cold conditions, remaining effective at temperatures as low as -20°C. Gummed kraft paper tape is also highly effective in cold environments due to its moisture-activated adhesive.

Is acrylic packing tape suitable for winter use?

Acrylic packing tape is water-based and performs best in temperatures above 15°C. It is not recommended for winter use or cold storage environments.

What is the strongest type of packing tape?

Gummed kraft paper tape is considered one of the strongest options, as it bonds directly to cardboard fibres. For pressure-sensitive tapes, solvent adhesive vinyl tape offers the highest long-term strength.

What is the difference between acrylic, hot melt, and solvent adhesives?

Acrylic adhesives are water-based and environmentally friendly, hot melt adhesives provide quick initial tack, and solvent adhesives offer superior performance in cold and demanding conditions.

Is paper packing tape strong enough for shipping?

Paper packing tape is suitable for light to medium-duty shipping. For heavier cartons or cold environments, reinforced paper tape or gummed kraft paper tape is recommended.

Is gummed paper tape better than plastic packing tape?

Gummed paper tape provides stronger adhesion, tamper evidence, and improved performance in cold or damp conditions. Plastic tapes are quicker to apply and suitable for general-purpose use.

What packing tape is best for ecommerce businesses?

Ecommerce businesses often use low noise tape for quiet operation, custom printed tape for branding, and gummed paper tape for secure, tamper-evident shipping.

Can packing tape be recycled?

Paper-based packing tapes are widely recyclable with cardboard. Plastic packing tapes may need to be removed before recycling, depending on local waste guidelines.